12

2024

-

11

What is Sheet Metal Fabrication?

Sheet metal fabrication refers to a process of processing metal sheets, mainly including methods such as shearing, punching, bending and forming. The process includes various cold stamping die structures and process parameters, as well as new stamping technologies and processes. The main processes of sheet metal fabrication include cutting, bending edges, bending forming, etc. 12

The application of sheet metal processing is very extensive, and common application areas include automobile body, chimney, iron furnace, etc. These products are typically made of thin metal sheets that undergo plastic deformation through manual or die stamping to form the desired shape and size, and may be formed into more complex parts through welding or minimal mechanical processing.

The specific operations of sheet metal fabrication include terms such as flattening, drilling, chamfering, etc., which play an important role in the processing of metal sheets.

Definition and Basic Concepts of Sheet Metal Fabrication

Sheet metal fabrication is a comprehensive cold working process for metal sheets (usually with a thickness of less than 6mm), including cutting, punching/cutting/composite, folding, welding, riveting, splicing, and forming processes. Its prominent feature is that the thickness of the parts is consistent. Sheet metal parts are usually processed through stamping, bending, stretching, and other methods, and the thickness remains unchanged during the processing.

Application fields of sheet metal fabrication

Sheet metal fabrication is widely used in various fields, such as electronics, communications, automotive industry, medical equipment, and construction industry. Common sheet metal products include TV cases, computer cases, mobile phone cases, metal cabinets, etc.

Equipment and process flow for sheet metal fabrication

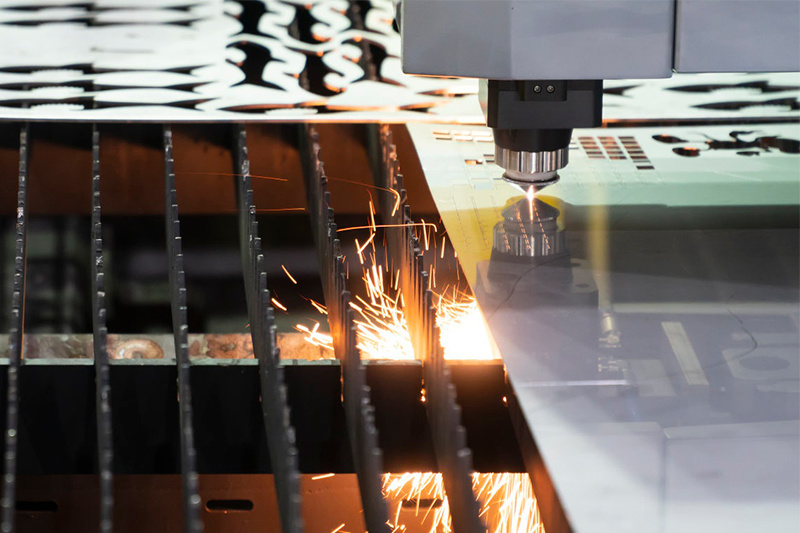

The main equipment for sheet metal fabrication includes shearing machines, CNC punching machines, laser cutting machines, bending machines, etc. The process usually includes the following steps:

Design: Design workpiece drawings according to requirements.

Cutting: Use a laser cutting machine or CNC punching machine for preliminary cutting.

Stamping: Stamping materials into shape using a punch press.

Bending: Use a bending machine to bend the material into the desired shape.

Welding: Connecting various components together through welding.

Surface treatment: Polishing, spraying, baking paint and other treatments are carried out to beautify the appearance and prevent rusting.

Advantages and disadvantages of sheet metal fabrication

Advantages:

Lightweight: Sheet metal parts are lightweight, making them easy to transport and install.

High compressive strength: possessing excellent mechanical properties.

Low cost: suitable for large-scale production with low cost.

Easy to process: Suitable for multiple processing methods, with high production efficiency.

Disadvantages:

High precision requirements: High skill requirements for equipment and operators.

Material limitations: Suitable for thin metal sheets, not suitable for thick metals or special materials.

In summary, sheet metal fabrication has a wide range of applications in multiple fields, with advantages such as lightweight, high compressive strength, and low cost. However, attention should also be paid to the limitations of processing accuracy and material applicability.

Sheet metal fabrication is a versatile process that continues to evolve with advancements in technology and materials. With the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, the design and production of sheet metal parts have become more efficient and accurate. Additionally, the development of new materials and coatings has expanded the possibilities for sheet metal fabrication, allowing for greater customization and durability.

One of the key advantages of sheet metal fabrication is its ability to create complex shapes and structures with high precision. This makes it an ideal choice for industries that require intricate designs, such as aerospace and electronics. Furthermore, the lightweight nature of sheet metal parts makes them ideal for applications where weight is a critical factor, such as automotive and aerospace industries.

Despite its many advantages, sheet metal fabrication does have its limitations. For example, the process is not suitable for thick metal sheets or materials that require high heat resistance. Additionally, the cost of equipment and skilled labor can be a barrier for smaller businesses looking to utilize sheet metal fabrication.

In conclusion, sheet metal fabrication is a crucial process in the manufacturing industry, with a wide range of applications and benefits. By understanding its capabilities and limitations, businesses can make informed decisions about incorporating sheet metal fabrication into their production processes. As technology continues to advance, the possibilities for sheet metal fabrication are only expected to grow.

Sheet metal fabrication is a versatile process that can be used to create a wide range of products with varying complexities. One common application of sheet metal fabrication is in the automotive industry, where it is used to create body panels, frames, and other components for vehicles. In the construction industry, sheet metal fabrication is used to create HVAC ductwork, roofing, and other structural elements. In the electronics industry, it is used to create enclosures for electronic components and devices.

One of the key advantages of sheet metal fabrication is its ability to create lightweight yet strong components. This makes it an ideal choice for industries where weight is a concern, such as aerospace and transportation. Additionally, sheet metal fabrication is a cost-effective manufacturing process, making it suitable for large-scale production.

In conclusion, sheet metal fabrication is a highly versatile and cost-effective process that is widely used in various industries. With the right equipment and expertise, sheet metal can be transformed into a wide range of products that meet the needs of different applications. Whether it is creating components for vehicles, buildings, or electronic devices, sheet metal fabrication offers a reliable and efficient solution for manufacturers.

XINLIN is a professional manufacturer of precision sheet fabricated parts, stamping parts, hydraulic parts, welding parts and moulds designing and making with more than10 engineers who are experienced in CAD,CAM for designing and many skilled employees working hard to build up a brand"XINLIN" on metal sheet field. Since 2001 all parts are well selling to UK, Germany, Italy, Norway, Greece, Iran, India, Pakistan, USA, Canada,Chile,Mexico, New Zealand, Australia etc. Customers such as Siemens, Coca Cola, PCORE, LAPP, FMC, JETWAY, EMD Technologies etc.